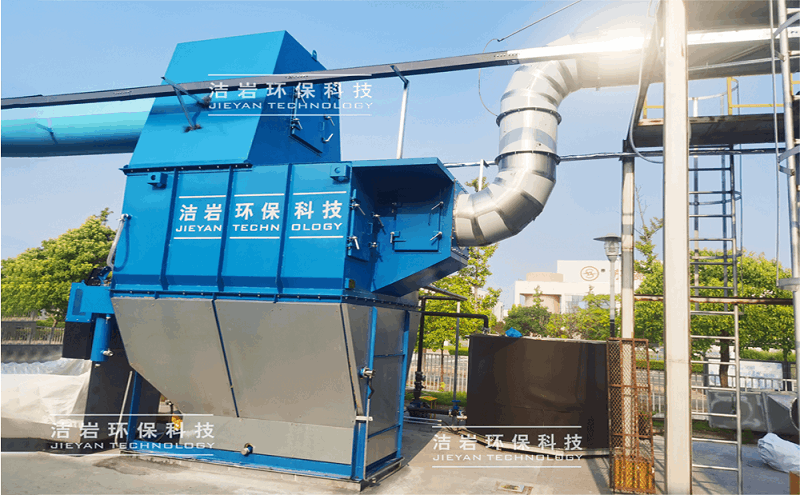

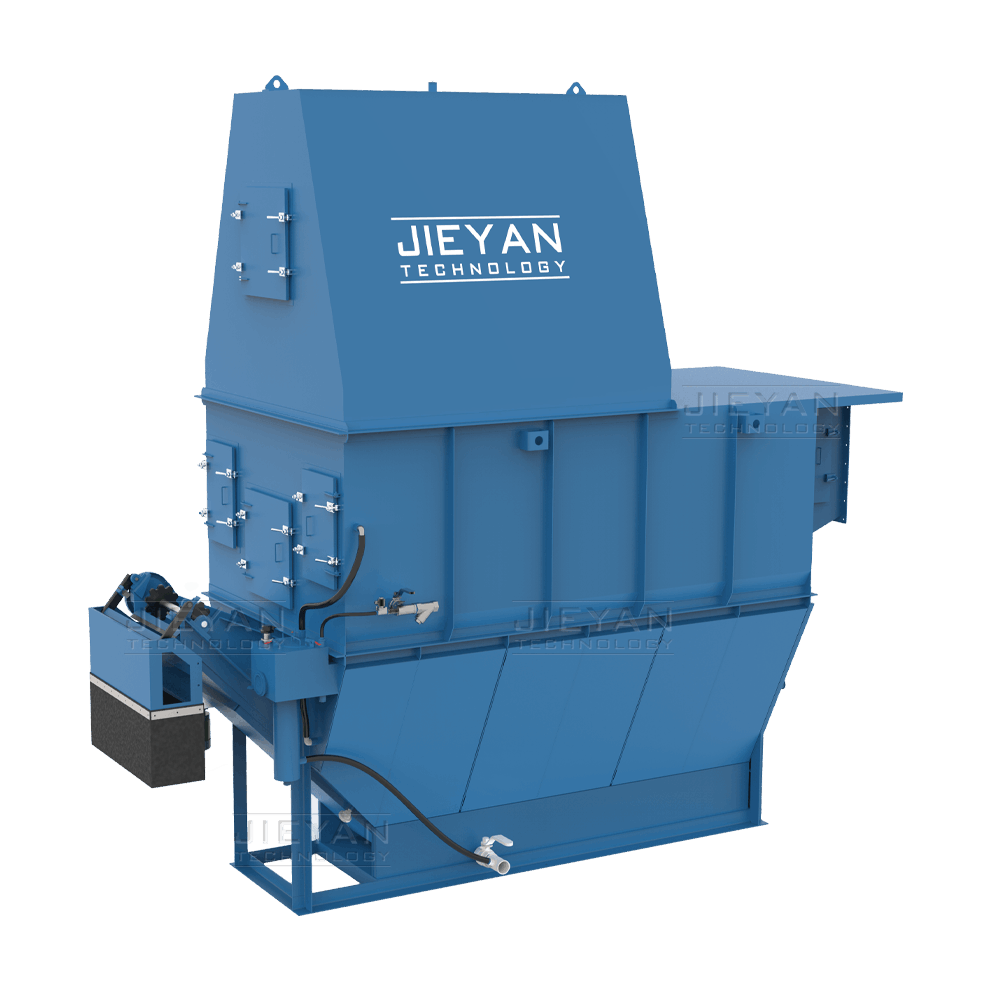

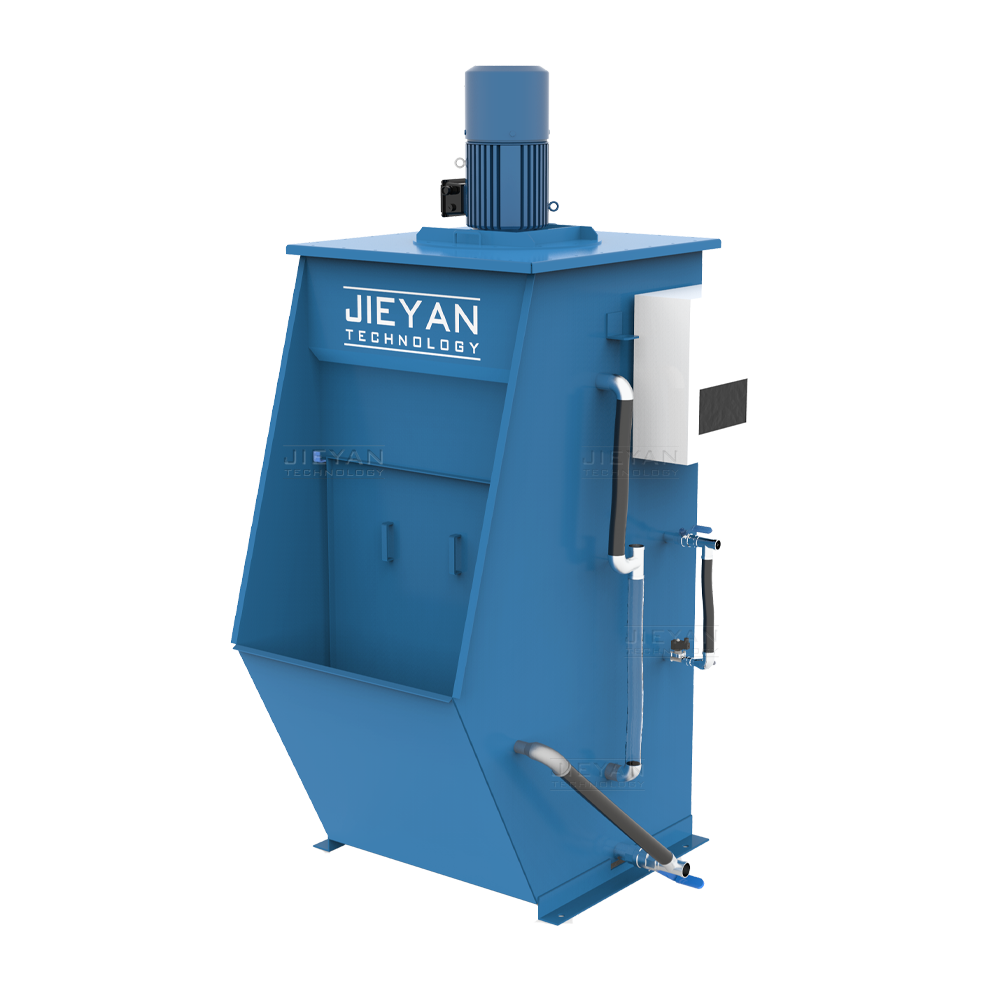

V Wet Collector

The V-series e wet dust collector is designed based on the principles of cyclone wet dustremoval and high-efficiency Venturi. It is used to process high concentration dust, make dustygases and liquids in close contact, and use gravity, inertia collision, interception, diffusion andother effects to capture particles or increase particle size. It can effectively remove liquid orsolid particles with a diameter of 0,1-20 μ m, as well as gaseous pollutants.

Viscous dust

Steam and oil fog

Flammable and explosive dust

Rubber / Leather / Plastic powder

Fiber / Fluff / Fabric dust

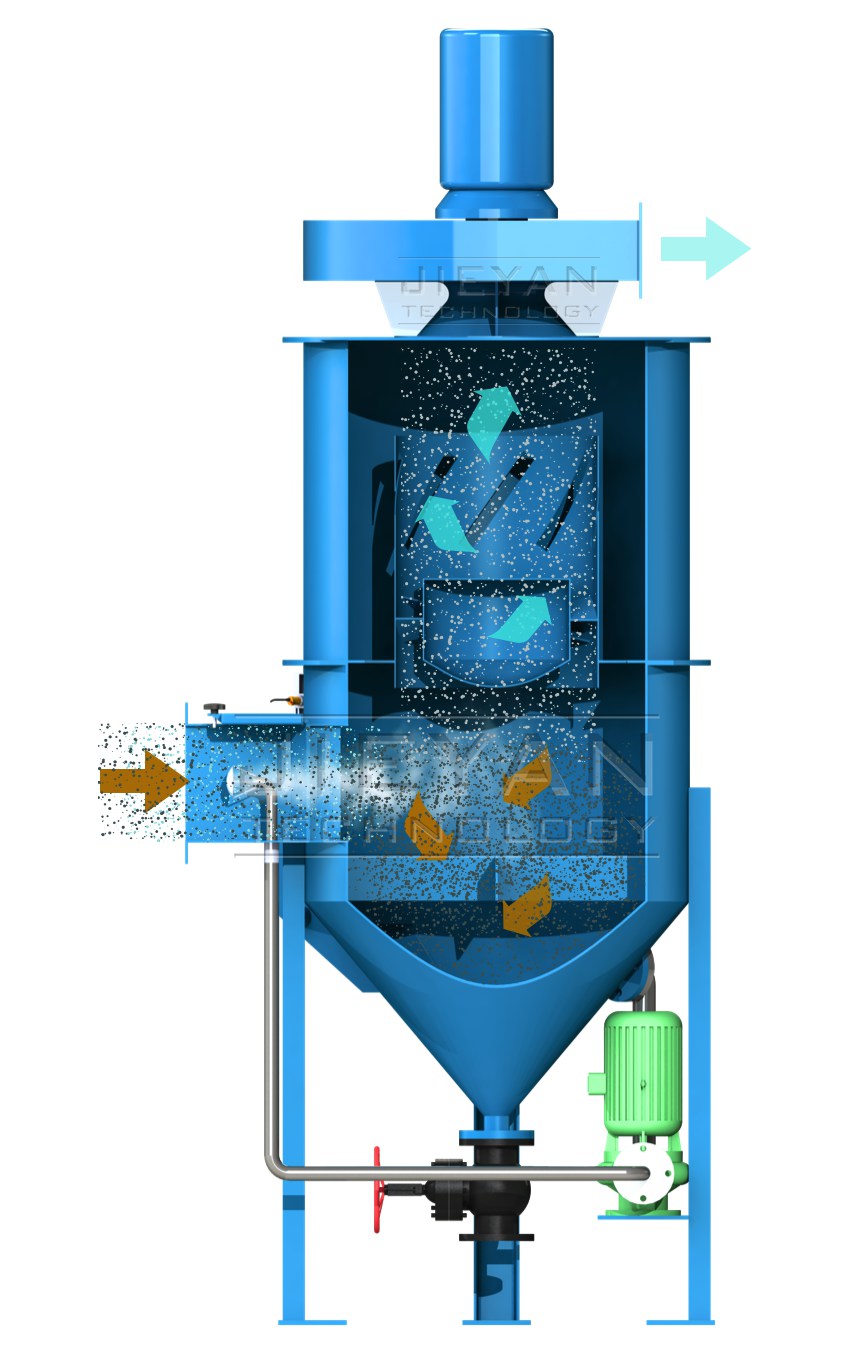

Dust removal principle of V-series swirl wet dust collector

- The V-series cyclone wet dust collector is designed to handle high concentration dust by combining cyclone wet dust removal and efficient Venturi principle. In the upstream area of the Venturi tube, washing water is injected, and the Venturi effect accelerates the airflow, causing the water flow to decompose into small water droplets

- At the throat of the Venturi tube, there is a strong interaction between dusty exhaust gas and water droplets. Pollutant particles and water droplets are fully mixed, and the washed exhaust gas and dusty liquid droplets tangential enter the downstream centrifugal separation structure to achieve separation

- After leaving the throat, the airflow enters the chamber of the cyclone dust collector, and the dusty airflow is introduced from the lower part of the cylinder. The special path of the airflow can generate strong water vortices, and the airflow containing dust is guided into this water vortex. These dusty droplets are captured and collected in the cyclone dust collector through gravity settling, centrifugal separation, and baffle interception, thereby achieving the separation of dust and gas

- After dust removal treatment, the gas becomes relatively clean and is finally discharged from the system through the outlet at the top of the dust collector

- In the washing water collection area, sedimentation separates pollutants

- The bottom sediment can be collected and cleaned in multiple ways

Tech Specs

| Model | Air volume(m³/H) | Equipment resistance(Pa) | Fan total pressure(Pa) | Fan power(KW) | Water pump flow rate(m³/H) | Water pump power(KW) |

| V2 | 2000 | ≤1800 Pa | 3500 Pa | 4 | 2 | 0.75 |

| V3 | 3000 | ≤1800 Pa | 3500 Pa | 5.5 | 3 | 0.75 |

| V4 | 4000 | ≤1800 Pa | 3500 Pa | 7.5 | 4 | 0.75 |

| V6 | 6000 | ≤1800 Pa | 3500 Pa | 11 | 6 | 0.75 |

| V8 | 8000 | ≤1800 Pa | 3500 Pa | 15 | 8 | 0.75 |

| V10 | 10000 | ≤1800 Pa | 3500 Pa | 18.5 | 10 | 0.75 |

| V12 | 12000 | ≤1800 Pa | 3500 Pa | 18.5 | 12 | 1.5 |

| V15 | 15000 | ≤1800 Pa | 3500 Pa | 18.5 | 15 | 1.5 |

| V18 | 18000 | ≤1800 Pa | 3500 Pa | 30 | 18 | 1.5 |

| V20 | 20000 | ≤1800 Pa | 3500 Pa | 30 | 20 | 1.5 |

| V25 | 25000 | ≤1800 Pa | 3500 Pa | 37 | 25 | 1.5 |

| V30 | 30000 | ≤1800 Pa | 3500 Pa | 37 | 30 | 2.2 |

*The above technical parameters are theoretical reference data. The theoretical throughput may vary

for different working conditions and materials. Please refer to the technical solution or technical

agreement parameters provided by the sales manager.

Related products

Contact Us

Welcome to follow Jieyan

JIEYAN WECHAT

JIEYAN TIKTOK

172 Xuanchun Road, Pudong New Area, Shanghai

021-68015579

13611679928

jieyanchina@163.com

021-20919219