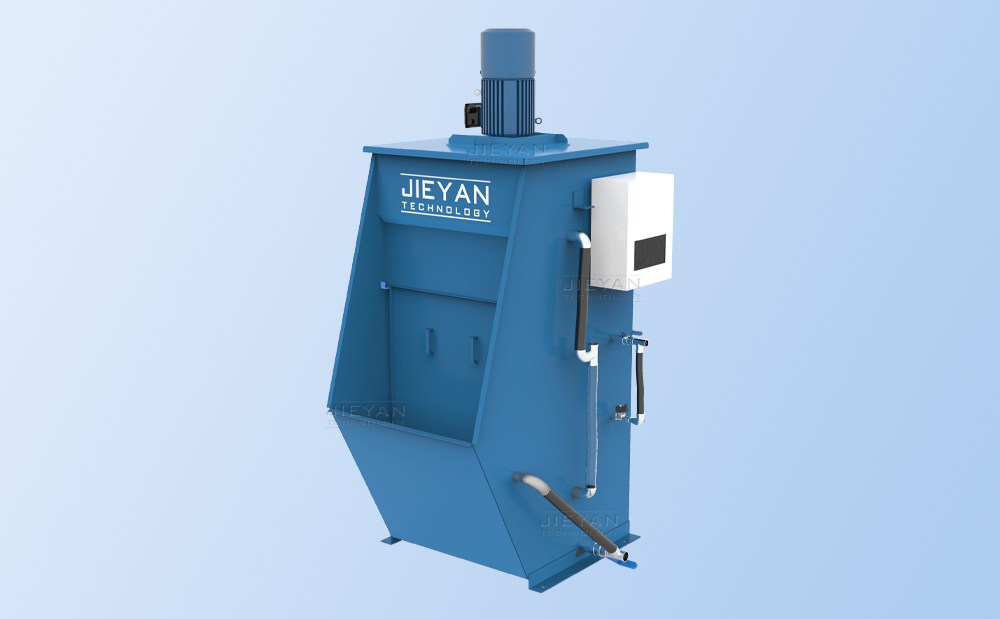

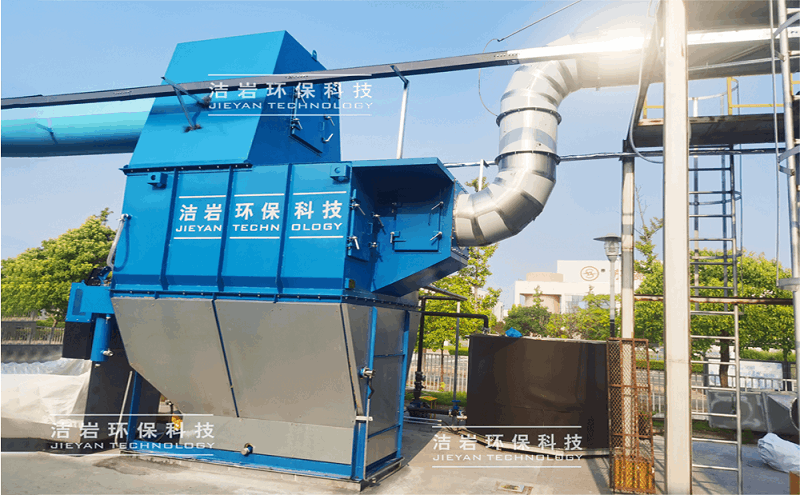

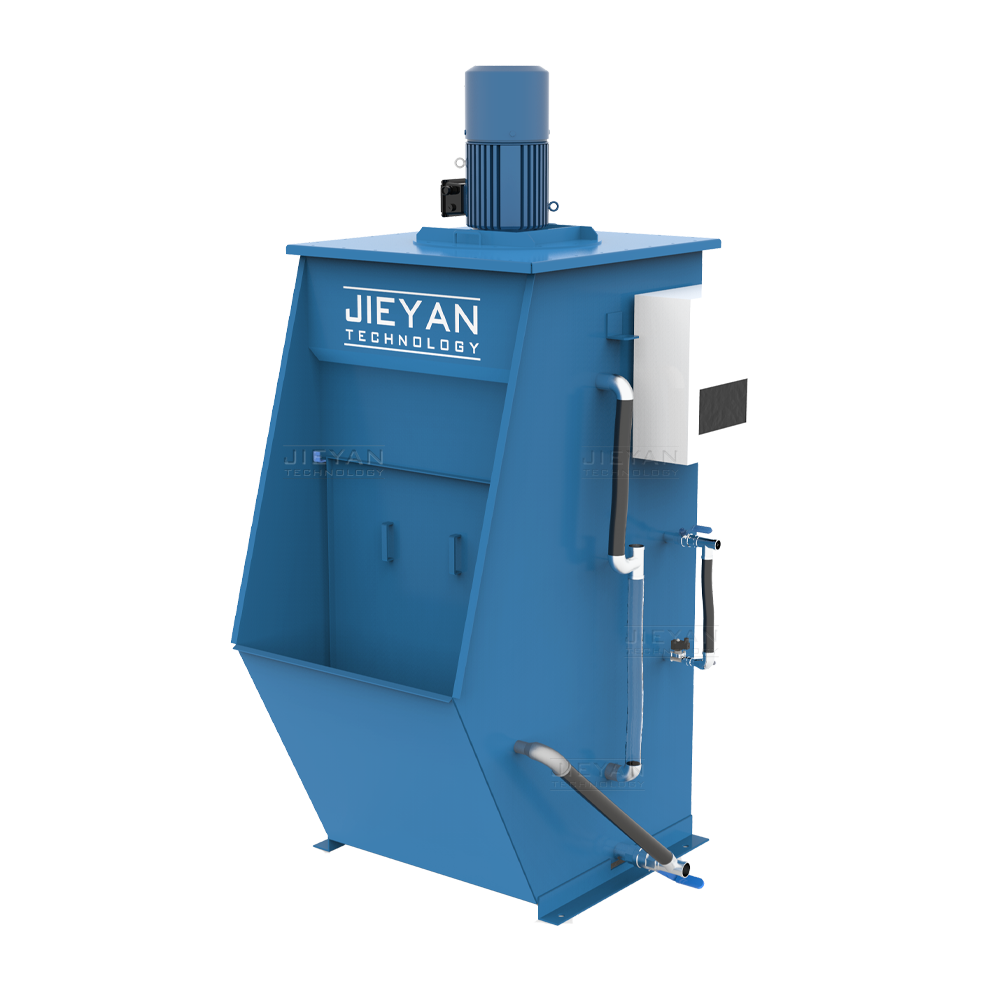

The LV wet centrifugal dust collector is a simple, efficient, and economical small humiditycollector for the dust generated by many industrial processes. LV type wet dust collectors aremainly used for small amounts of dusty gases, such as dust removal on polishing tables, specificsingle station dust removal, and single machine matching of polishing machines .

Viscous dust

Polishing dust

Steam and oil fog

Flammable and explosive dust

Fiber / Fluff / Fabric dust

Working principle of LV wet centrifugal dust collector

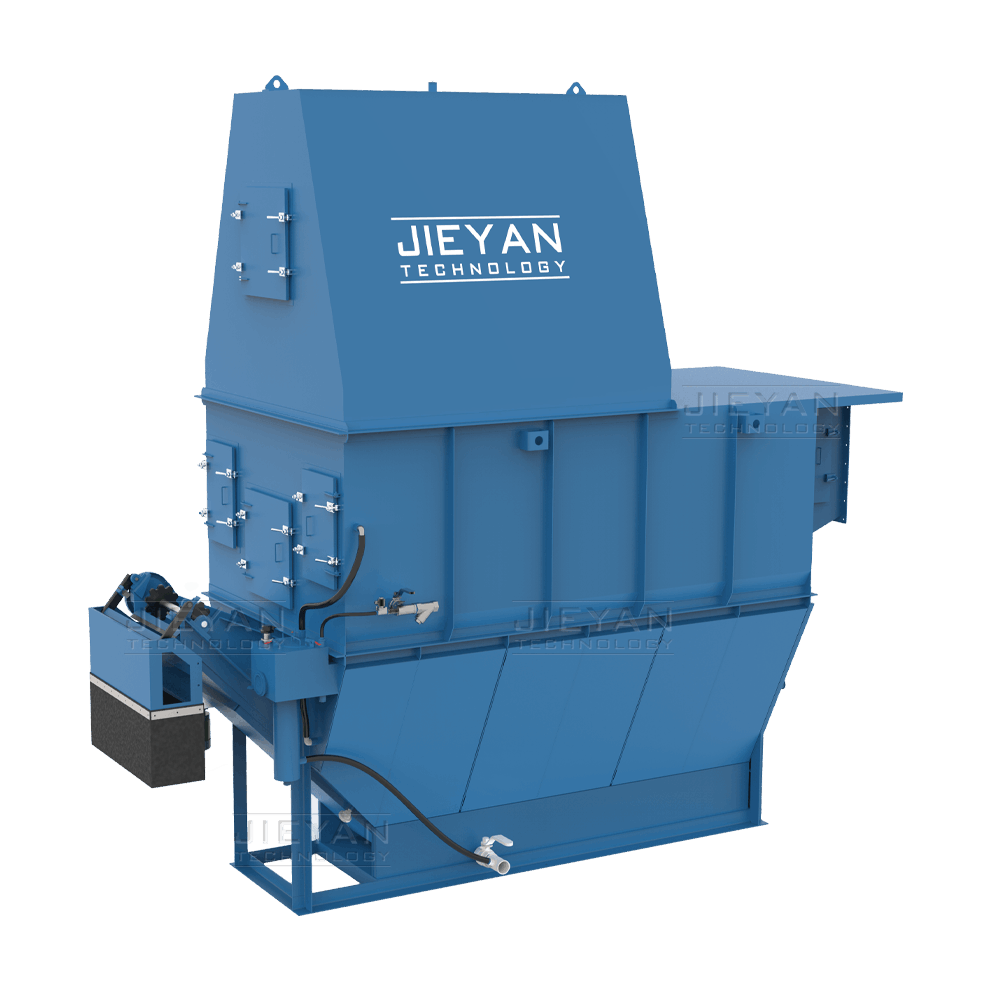

The LV model wet dust collector purifies air by combining centrifugal force, allowing water and dusty gases to mix thoroughly. High speed airflow passes through a fixed impeller to generate a water curtain. When dust in the airflow passes through the water curtain, centrifugal force is generated due to the rapid change in air flow direction, causing dust particles to penetrate water droplets and be permanently trapped in the water. Due to the presence of three defogging baffles, water mist filled with dust will be removed from the airflow. Dust eventually settles at the bottom of the equipment, and water can also be reused. A water curtain is generated by the impact of airflow on the water surface, without the need for a pump or nozzle.

The LV type wet dust collector is designed based on the HDC series equipment. As an efficient, compact, and economical wet dust collector, it can handle dusty gases up to 4000CMH.

Nowadays, while the basic working principle remains unchanged, we have optimized and improved many details of the dust collector, and the results are very significant. The LV type wet dust collector provides an efficient and reliable method for controlling dust in the factory at a very low maintenance cost.

Technical Features

✦ Two nominal sizes,1.000CFM and 2,000CFM

✦ Proven Type HDC collector design

✦ Built-in centrifugal fan

✦ Direct drive-no belts requiring changing or adjustment

✦ Standard 11-gauge construction

✦ Attractive (flush) cabinet-type housing design

✦ Painted exterior finish

✦ Combination access door/explosion vent

✦ Large 2" drain coupling for cleaning

✦ Simple liquid level control

✦ Sloped wall for easy sludge removal

✦ No moving components(except fan)

✦ Non-clogging/low build-up water entrainment

✦ Separators reduce maintenance

✦ Compact design

✦ No water overflow

✦ Low maintenance

✦ Vertical airflow-minimal floor space required

✦ Built-in safety features for light metal working

✦ Low water safety controls

✦ Automatic water level controls

Tech Specs

| Model | LV-2 M | LV-3 M |

| Processing air volume(m3/h) | 2000-3000 | 3000-4000 |

| Power(kw) | 3 | 5.5 |

| Pressure loss | 1643-1892 | 1643-1892 |

| Purification efficiency(%) | 99 | 99 |

| Noise | 75 | 75 |

| External dimensions(mm) | 1085*902*2130 | 1362*1116*2400 |

| Operating weight(kg) | 1023 | 1243 |

| Filling water volume(m³) | 0.35 | 0.47 |

| Transport weight(kg) | 634 | 721 |

| water consumption(CMH) | 0.11 | 0.11 |

Related products

Contact Us

Welcome to follow Jieyan

JIEYAN WECHAT

JIEYAN TIKTOK

172 Xuanchun Road, Pudong New Area, Shanghai

021-68015579

13611679928

jieyanchina@163.com

021-20919219