News information

-

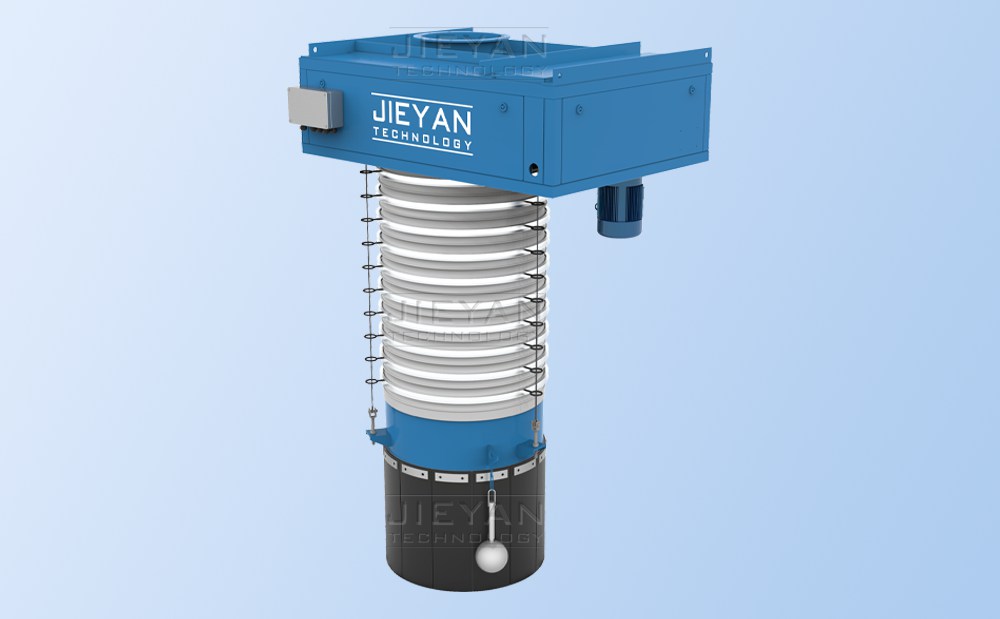

The commissioning and advancement of Jieyan's ship loading spouts will contribute to the dust-free bulk material loading of ships at Nanjing Port.

【2025-04-07】

The Jieyan TL series ship loading spouts have excellent performance. The stroke ranges from 6000 to 25000mm, and the unloading capacity is 2100 to 5800m³/H. It has a wide range of applicability and can be used for handling materials such as ores, aggregates, grains, and coal. It is suitable for operations in mine stockyards, high-altitude material throwing of ores and ore powders, as well as ship loading operations at port terminals.

-

The loading spouts for coal ship loading at Zhoushan Port are currently undergoing commissioning...

【2025-03-31】

As a crucial coal transfer hub along China's coast, Ningbo Zhoushan Port has long handled massive coal loading/unloading operations. The loading spouts currently being commissioned, specially designed for coal vessel loading at the port, will significantly transform coal handling operations with their advanced functionalities. These innovations are expected to enhance loading efficiency while reducing dust pollution.

-

What are the implementation methods and approaches for the intelligent tanker docking system?

【2023-12-28】

The system mainly consists of a positioning device, sensor system, control system, and auxiliary devices. During the docking operation, the positioning device obtains the relative position and posture information of the tanker truck and the loading/unloading platform through the sensor system. The control system calculates the action amount and action sequence of each actuator based on the acquired information. The control system's instructions guide, position, and dock the positioning device.

-

The Principles and Advantages of the Intelligent Cement Tanker Loading System

【2023-12-28】

The principle of the intelligent cement tanker loading system is to achieve fast and accurate cement loading through automation and intelligent technology. The system integrates high-precision sensors and measurement devices, capable of accurately measuring the weight and volume of cement, thus avoiding inaccuracies caused by human factors. Additionally, the system employs intelligent planning and motion control technology, enabling precise proportioning based on actual requirements, optimizing resource utilization.

-

The Application of Tanker Intelligent Loading System in Bulk Cement Handling

【2023-12-28】

The intelligent loading system uses automation and intelligent technology, enabling fast and accurate cement loading, significantly improving loading efficiency and reducing the complexity and errors associated with manual operations.

-

Sand and Gravel Aggregate Loading Bulk Machine - Telescopic Chute.

【2023-06-29】

The application of the intelligent fast loading system addresses the issues of high labor intensity, difficulty in manual loading, and low efficiency during the loading process. Moreover, while ensuring safety, the intelligent fast loading system improves loading quality, simplifies the loading process, and reduces production costs.

-

The application of bulk machines in dust collection for sand and gravel aggregates, construction materials loading onto ships and trucks, and bottom unloading dust collection.

【2022-11-16】

During the process of sand and gravel aggregates being transferred into the storage bin via a conveyor belt, a significant height difference exists, which causes a large amount of dust to be generated during unloading. This dust rapidly spreads within the material shed and can lead to pollution within the plant area.

-

Ship Loading Machine Telescopic Chute - Port Ship Loading Special Equipment

【2022-12-02】

The telescopic chute, also known as a bulk loader, telescopic chute pipe, or telescopic section, is specifically designed and developed for bulk material handling. It primarily addresses the issue of dust dispersion during the loading and unloading of powdery materials.

-

Port Dock Ship Loading Machine Bulk Material Handling Special Telescopic Chute - Bulk Machine

【2022-12-13】

The telescopic chute, also known as a bulk material loader, telescopic pipe, or telescopic section, is specifically designed for the handling of bulk materials. It primarily addresses the issue of dust dispersion during the loading and unloading of powdery materials.

-

The application of bulk machines in dust removal for the loading of sand and gravel aggregates, construction materials onto ships and trucks, and unloading dust removal from warehouse bottoms.

【2022-12-02】

The sand and gravel aggregate bulk machine is a device equipped with a filtration system. During the loading of sand and gravel aggregates, since the aggregate loading machines do not allow the installation of bag filters, it becomes increasingly essential and urgent to include a filter bag dust removal system in the bulk machine.

-

Special dust collector for bulk material loading and unloading at port terminals - telescopic chute - bulk machine

【2022-11-16】

The general cargo at the bulk cargo port terminal is coal, iron fine sand, grain, etc. These inventories are often fine and lightweight, and during storage, transportation, and loading and unloading, serious dust pollution will occur, especially during windy seasons.