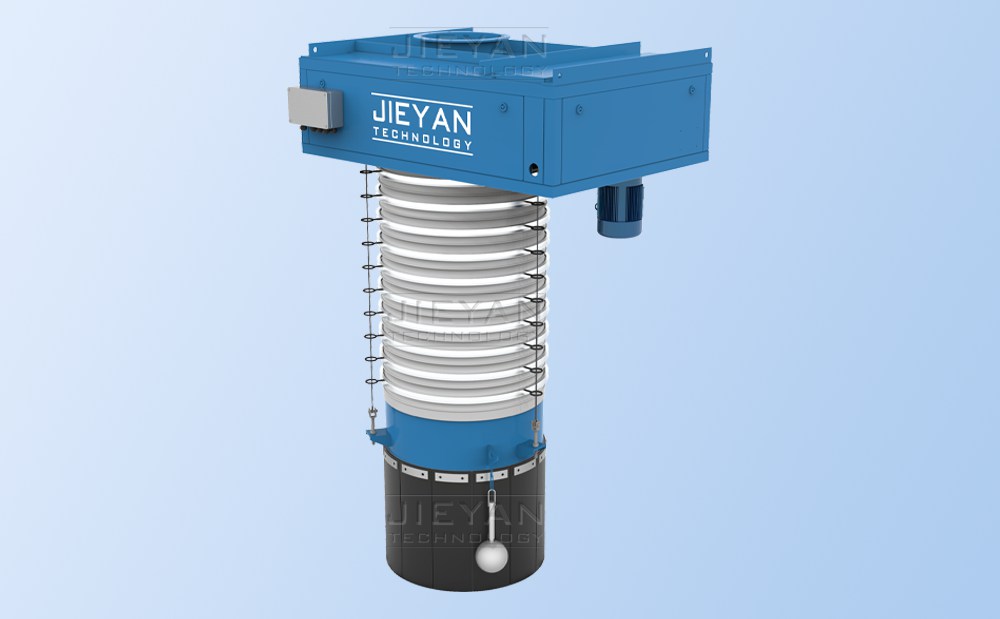

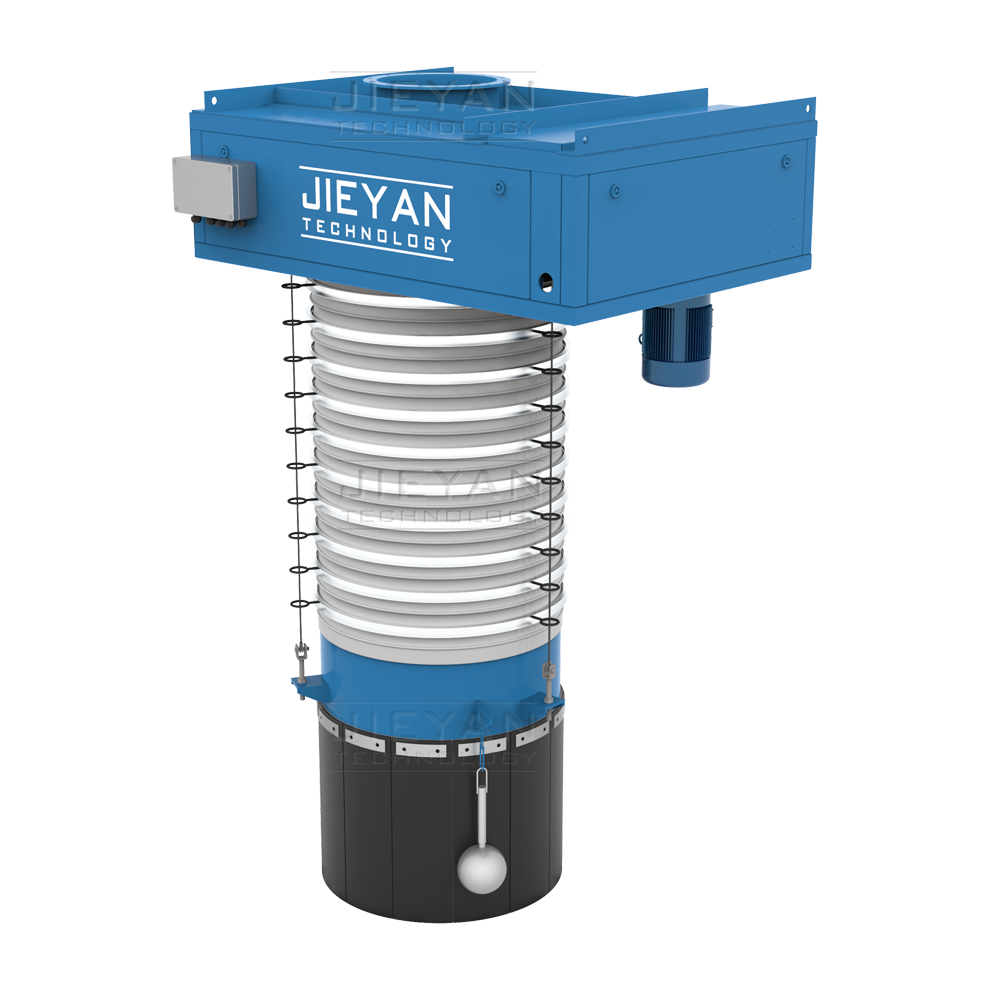

Sand and gravel aggregate bulk machine

The sand and gravel aggregate bulk machine is a device equipped with a filtration system. During the loading of sand and gravel aggregates, since the aggregate loading machines do not allow the installation of bag filters, it becomes increasingly essential and urgent to include a filter bag dust removal system in the bulk machine. This trend is inevitable. The bulk machine consists of key components, including an electrical control box, motor, reducer, pulley system, telescopic pipe, dust suction pipe, steel wire rope, and others. These components are connected via steel wire ropes and suction pipes to form a retractable structure. When the bulk head cone surface descends and fits tightly with the top of the truck’s dust inlet, the lower limit switch sends a signal to the control system, shutting off the winch motor and activating the dust extraction machine and butterfly valve. The material begins to fall into the truck. When the material fills the tank, the level sensor sends a signal to the control system, which automatically shuts off the feeder and the dust extraction fan, and lifts the bulk head. Once the bulk head approaches the upper limit position, the upper limit switch sends a signal back to the control system to automatically shut off the winch motor.