Dust Collector for LOADING SPOUTS

- The BF series telescopic chute dedicated dust collector is a specialized dust removal equipment designed for the transportation of loose materials in the telescopic chute of ship loaders. This dust removal module is highly integrated, small in size, compact in structure, and does not require the connection of dust removal ducts. It can adapt to the vast majority of bulk machines and telescopic chutes on the market. The dust collected by the TD series telescopic drum dedicated dust collector will be discharged back into the material pile without the need for secondary treatment. It is currently the most ideal and efficient dedicated dust collector for the end of the chute.

- Compact structure, light weight, and small increase in load

- Strong applicability, suitable for most ship loaders with telescopic chutes

- Integrated control box that can be interlocked with the existing chute control system

- High performance filter element with long service life

- Online dust removal without the need for dust removal

- Quick disassembly design, quick and convenient replacement of filter cartridges

Performance characteristics

01 Compact structure, light weight, and small increase in load

The BF series chute dedicated dust collector adopts a compact design, reasonable structure, uniform and symmetrical load, light equipment weight, and small additional load. Most ship loaders can withstand it.

02 Strong applicability, suitable for most existing ship loaders with telescopic chutes on the market

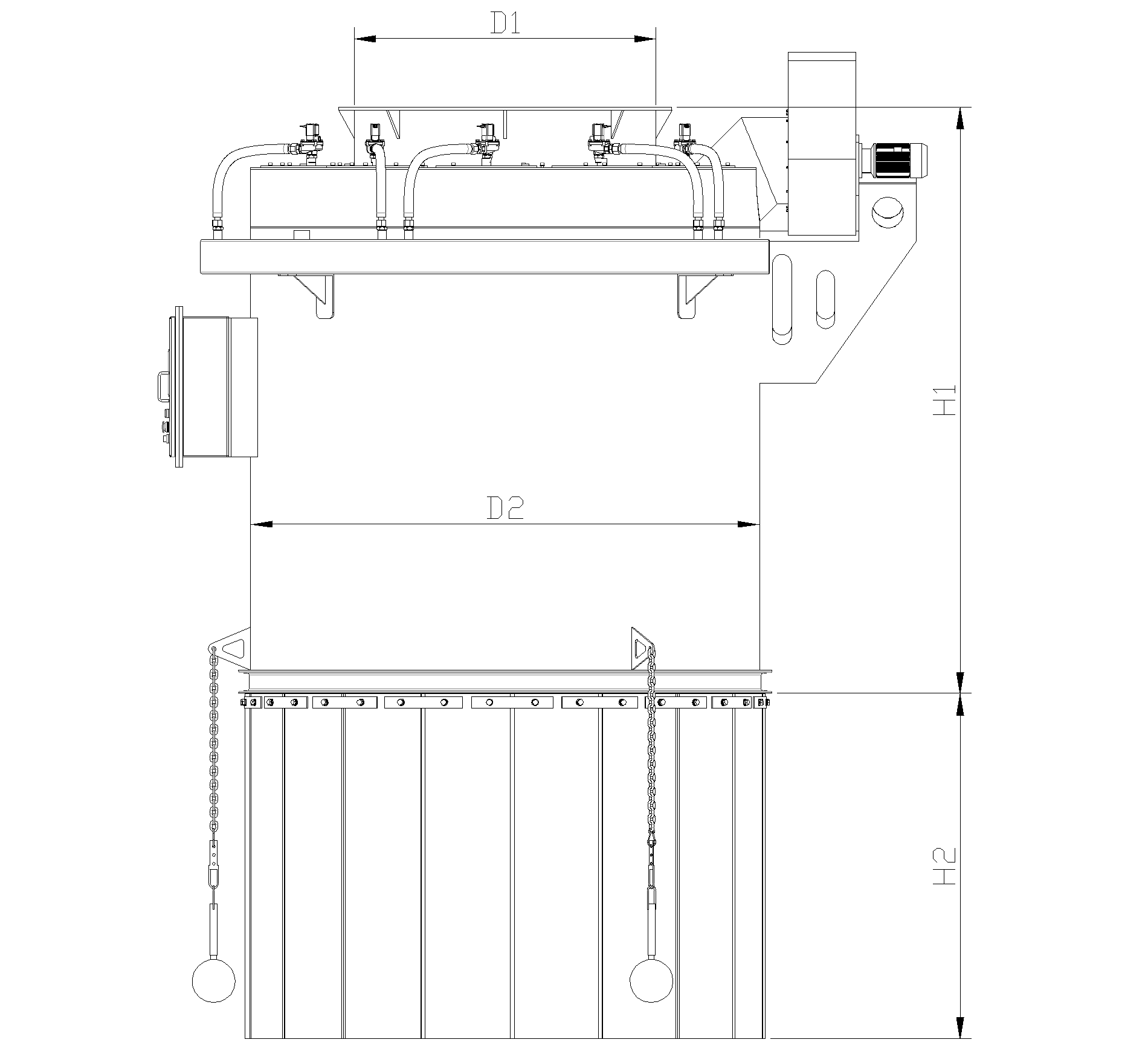

The BF series chute dedicated dust collector adopts a symmetrical design, and the equipment is installed at the bottom of the telescopic chute. It is connected to the existing chute bottom through a flange, which does not occupy additional space on the upper part of the ship loader. It can be used for most existing ship loader telescopic chutes on the market.

03 Close to the dust source, high dust collection efficiency, and low equipment power consumption

The BF series chute dedicated dust collector is installed at the bottom of the chute. The dust and air disturbance generated by the material sliding over the chute and impacting the material pile are immediately collected by the dust collector, with high dust collection efficiency and less dust overflow; Because the dust collector is close to the dust source, only a small suction force is needed to control the overflow of dust, so the power of the dust removal fan is low and energy consumption is low.

04 Strong applicability, suitable for most existing ship loaders with telescopic chutes on the market

The BF series chute dedicated dust collector adopts PTFE coated polyester fiber filter element, which is water and oil resistant, with a filtration accuracy of 1 micron (0.1-15 microns are optional), and has a long service life. It is suitable for various fields such as ports and docks, metallurgy and mining, building materials and chemical engineering. The filter element adopts a quick disassembly installation, which is easy to disassemble and maintain.

05 Online dust removal without the need for dust removal

The BF series chute dedicated dust collector integrates an online pulse cleaning system. During the use of the dust collector, the dust attached to the filter element is cleaned in real-time according to the set program. The cleaned dust directly enters the bottom of the dust collector and falls into the material pile along with the material flow, eliminating the need to handle the dust removal ash and reducing maintenance workload.

06 Integrated control box that can be interlocked with the existing chute control system

The BF series chute dedicated dust collector is equipped with a standard control box, which can achieve program control of the dust removal fan and pulse valve, and can also be connected to the existing ship loading machine central control system to achieve interlocking control.

Tech Specs

| internal diameter D1 | D1(Customized according to on-site conditions) |

| external diameter D2 | D1+700mm |

| Dust collector height H1 | 2200mm |

| Rubber skirt edge height H2 | 1200 |

| Dust removal air volume | 4000~8000m³/H |

| Fan power | 3~8KW |

| filtration velocity | 1.5m/min |

| Dust cleaning method | Pulse valve automatic dust cleaning |

| Increase load | ≤1000KG |

Contact Us

Welcome to follow Jieyan

JIEYAN WECHAT

JIEYAN TIKTOK

172 Xuanchun Road, Pudong New Area, Shanghai

021-68015579

13611679928

jieyanchina@163.com

021-20919219